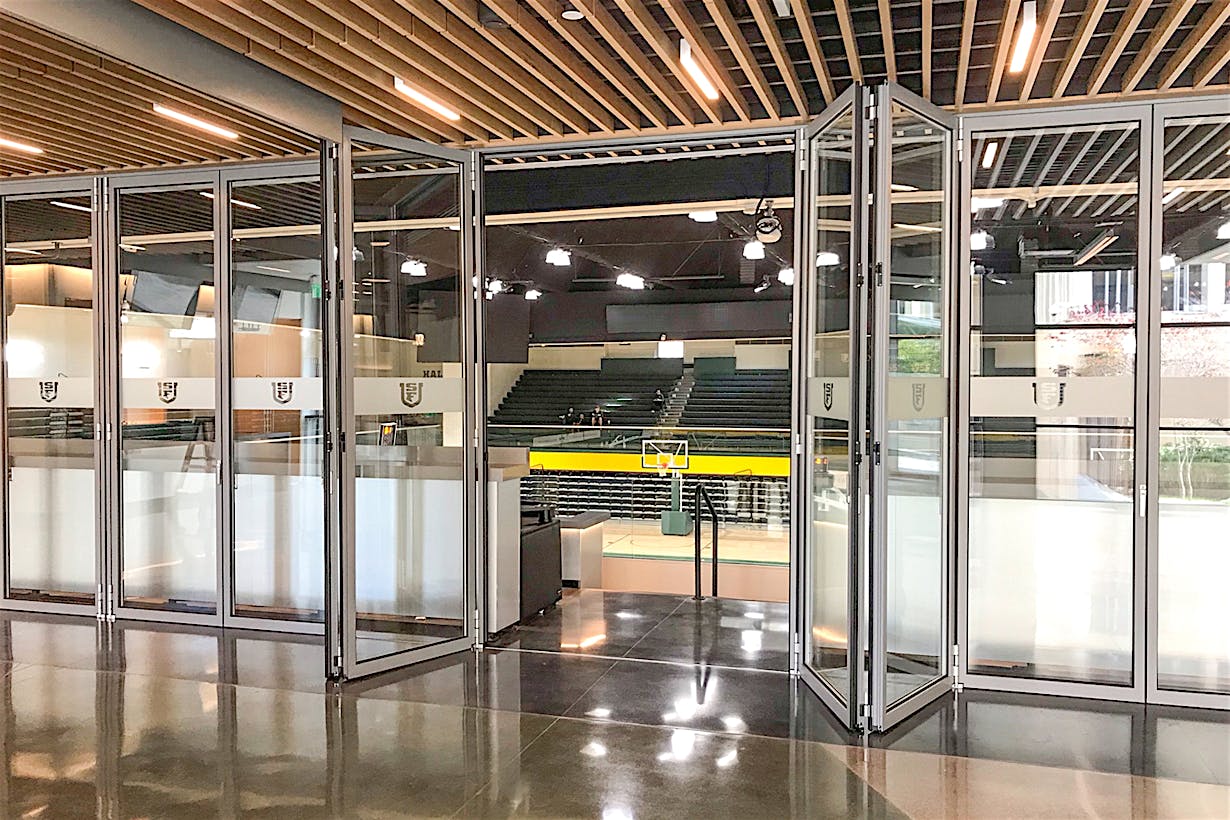

Explore some examples of customized solutions to visualize the versatility of our products. Let us know how we can help bring your design to life.

For over 30 years, we’ve been leading the industry in developing and refining our glass wall systems to create solutions across every application.

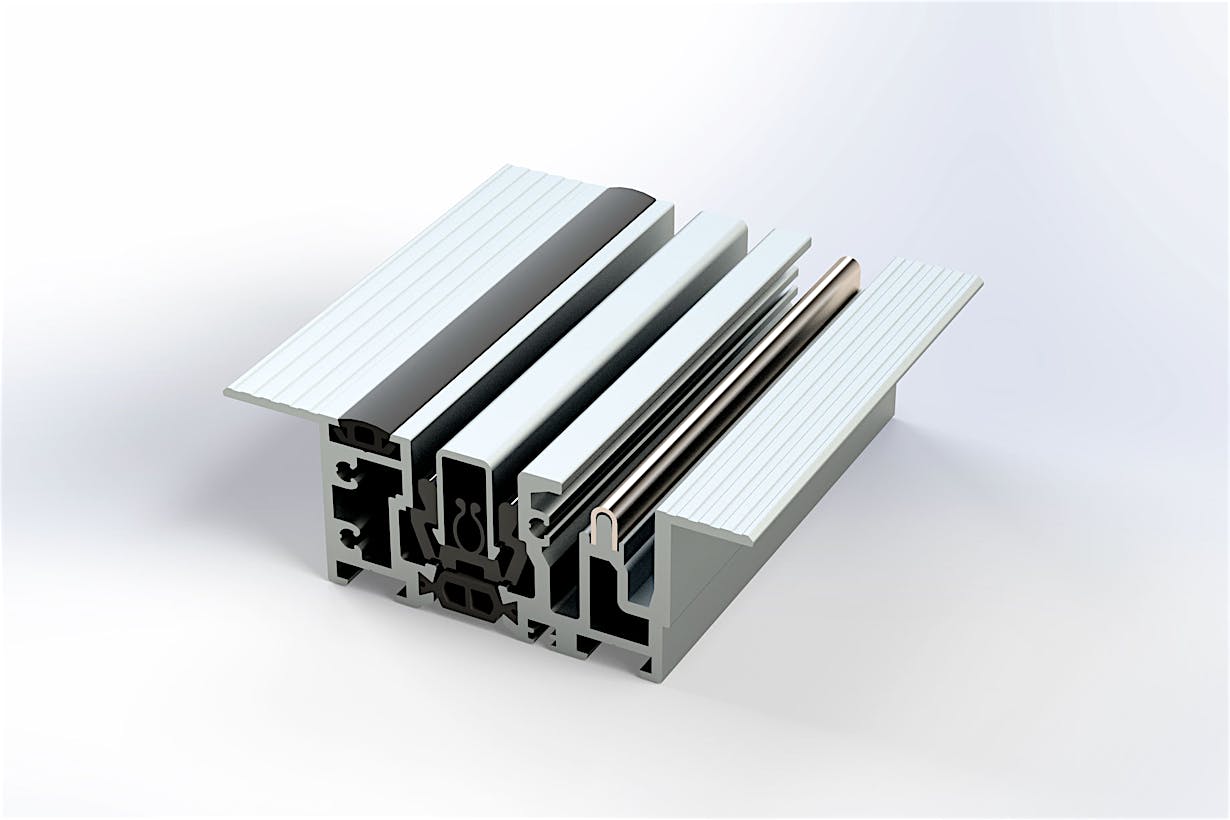

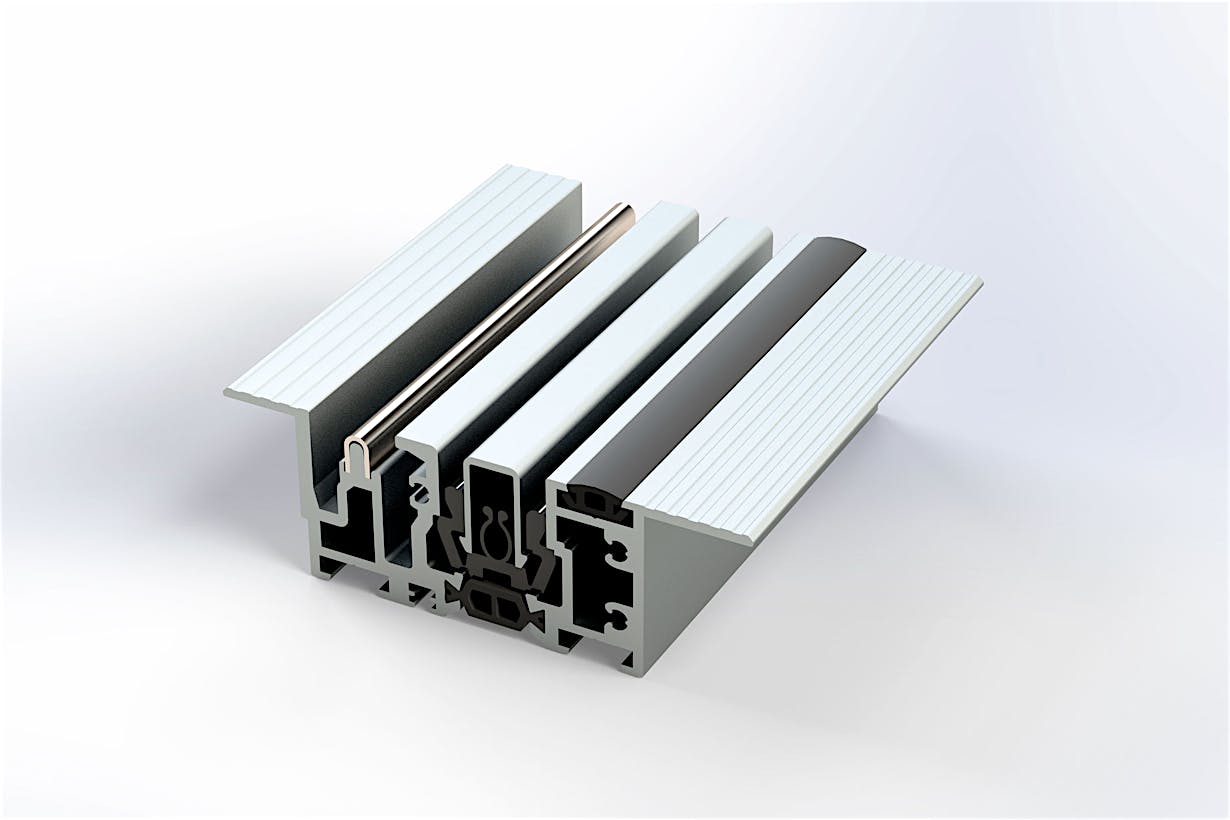

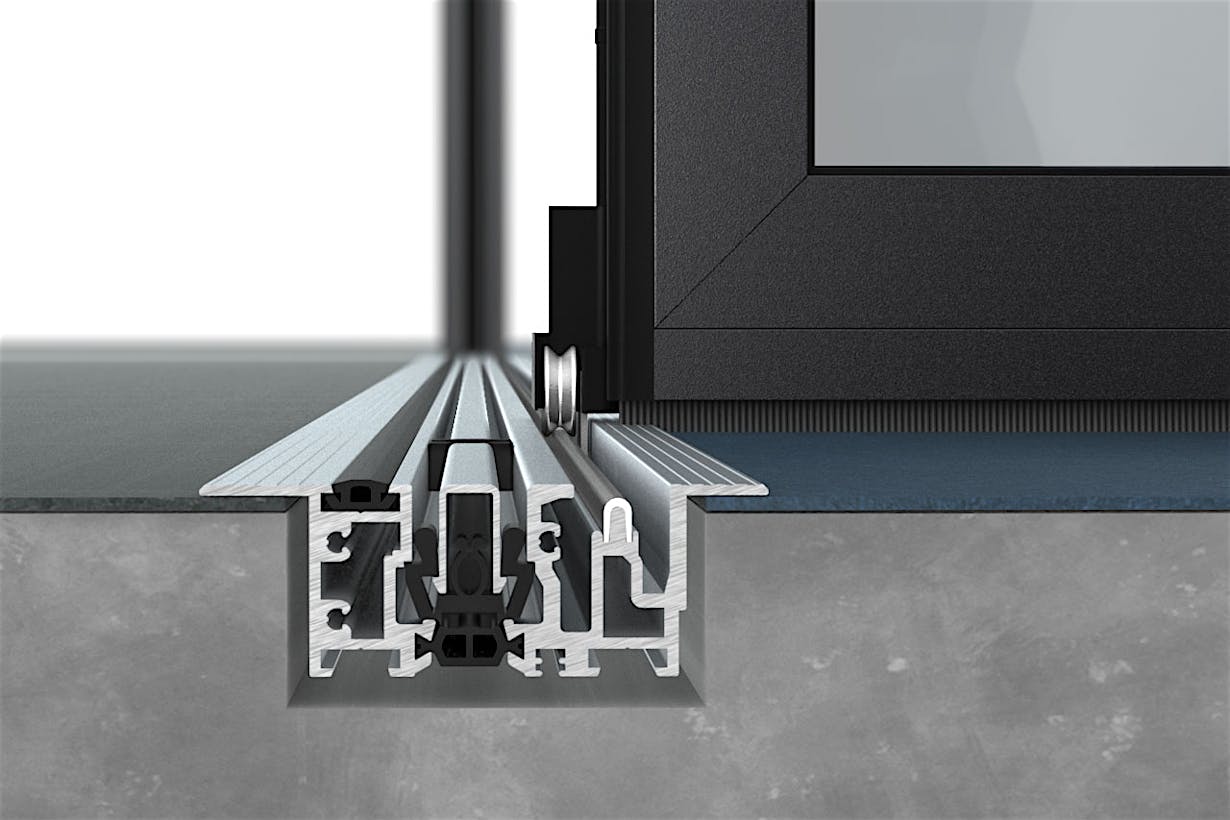

Flush Sill

- Fully recessed into floor to create flush profile, virtually disappearing

- ADA-compliant with insert

- Thermally broken for better insulation and energy efficiency

- Designed for interior applications

- Fully recessed into floor to create flush profile, virtually disappearing

- ADA-compliant with insert

- Thermally broken for better insulation and energy efficiency

- Designed for interior applications

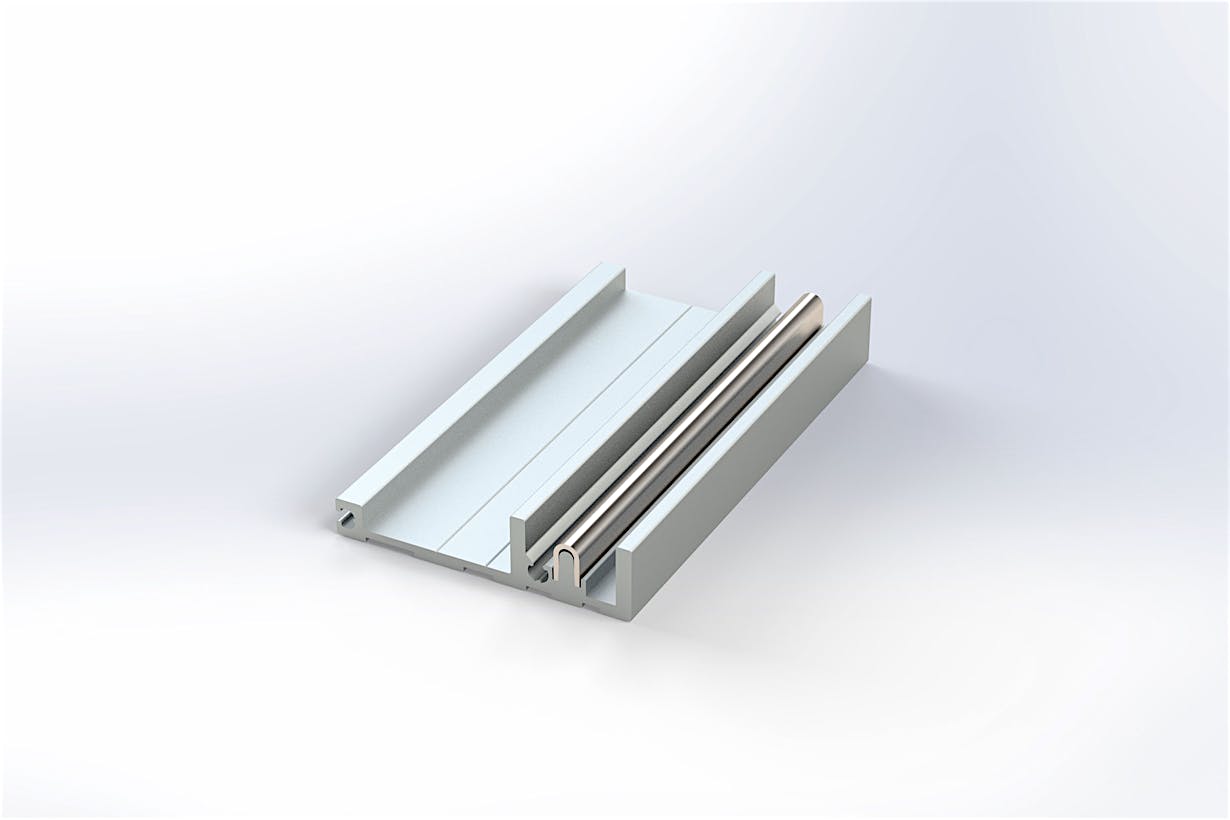

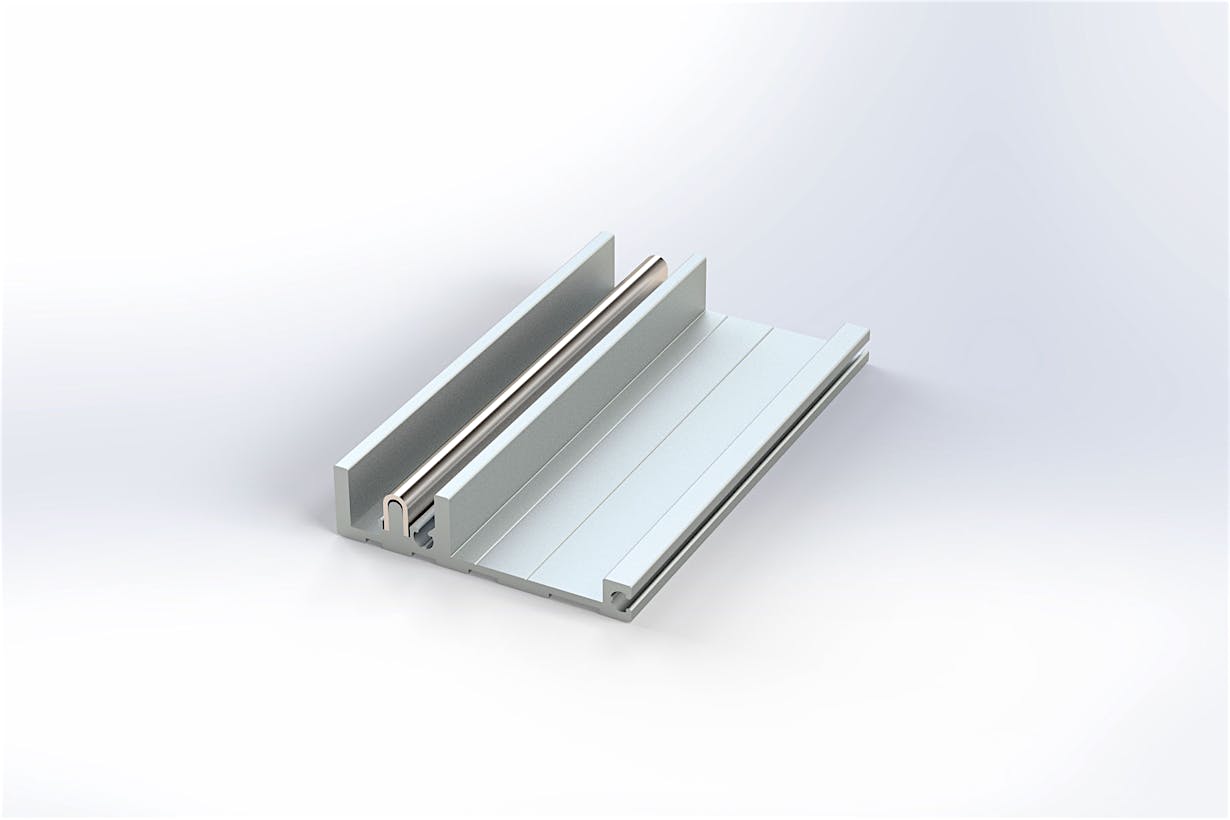

Surface Mounted Flush Sill

Designed specifically for interior applications, the surface mounted flush sill is ADA compliant and when installed with finished flooring, has only a mere 15/16” (23.5 mm) visible grove.

The shallow surface mounted sill allows for easy installation. Sill can be installed on the foundation or sub-floor and finished flooring can butt up to the floor track creating seamless integration between interior spaces

Designed specifically for interior applications, the surface mounted flush sill is ADA compliant and when installed with finished flooring, has only a mere 15/16” (23.5 mm) visible grove.

The shallow surface mounted sill allows for easy installation. Sill can be installed on the foundation or sub-floor and finished flooring can butt up to the floor track creating seamless integration between interior spaces

Stainless Steel Lever Handles

Stainless steel lever handles and escutcheon plates are available either in a brushed satin, black titanium finish.

Stainless steel lever handles and escutcheon plates are available either in a brushed satin, black titanium finish.

Contemporary Stainless Steel Handle

Stainless steel flat handles are available either in a brushed satin, black titanium finish.

Stainless steel flat handles are available either in a brushed satin, black titanium finish.

Spring-Loaded Pull Handle

For outswing units with larger panel sizes, a spring-loaded pull handle is supplied for ease of closing the system. The pull handle is located above the flat handle. When not in use, the handle lays flat against the adjacent panel and is supplied with bumpers to avoid metal-to-metal contact. Handles are either silver or black titanium stainless steel with the attachment to coordinate with the hinge hardware of the system.

For outswing units with larger panel sizes, a spring-loaded pull handle is supplied for ease of closing the system. The pull handle is located above the flat handle. When not in use, the handle lays flat against the adjacent panel and is supplied with bumpers to avoid metal-to-metal contact. Handles are either silver or black titanium stainless steel with the attachment to coordinate with the hinge hardware of the system.

Stainless Steel Lever with Return

Multipoint Locking with Latch, Deadbolt and Top/Bottom Locking Rods

Standard and Tested Locking Option on Primary Swing Panels:

Multipoint locking operated by lever handles and with European profile cylinder. Locking is independently tested for acoustical performance and forced entry. Instead of a profile cylinder, an adapter casing is available for use with an SFIC core.

Includes top and bottom Polyamide capped locking rods, deadbolt, a compatible lock set with lockable latch and lever handles on the inside and outside. Depression of handles withdraws latch. Lifting of handles engages rods and turn of key or thumb turn engages deadbolt and operates lock.

Operable from inside and outside.

Standard and Tested Locking Option on Primary Swing Panels:

Multipoint locking operated by lever handles and with European profile cylinder. Locking is independently tested for acoustical performance and forced entry. Instead of a profile cylinder, an adapter casing is available for use with an SFIC core.

Includes top and bottom Polyamide capped locking rods, deadbolt, a compatible lock set with lockable latch and lever handles on the inside and outside. Depression of handles withdraws latch. Lifting of handles engages rods and turn of key or thumb turn engages deadbolt and operates lock.

Operable from inside and outside.

Two Point Locking

Standard to the system is concealed locking between folding panels that operates with a 180° turn of a flat handle. The top and bottom locking bolts have approximately a 1″ (24 mm) throw for maximum security engagement into the head and floor track.

Operable from inside only.

Standard to the system is concealed locking between folding panels that operates with a 180° turn of a flat handle. The top and bottom locking bolts have approximately a 1″ (24 mm) throw for maximum security engagement into the head and floor track.

Operable from inside only.

Optional Commercial Locking

For Primary Swing Panels (no acoustical performance value)

- Deadbolt lock(s) and push/pull handles and key/key European profile cylinder on both sides. Only recommended for end swing panel with door closer by others. Instead of a profile cylinder, an adapter casing is available for use with an SFIC core.

- Latch and deadbolt single motion operated by GU Rondo lever handles and with European profile cylinder. Instead of a profile cylinder, an adapter casing is available for use with an SFIC core.

For Primary Swing Panels Prepped for Supply by Others (no acoustical performance value)

- Latch and deadbolt single motion locking operated by lever handles with locking with a US mortise cylinder that can accommodate standard 5 - 7 pin, SFIC, FSIC, or LFIC cores that currently includes Yale 8808-2 series and Schlage L/LV9000 series only.

- Single latch Schlage ND Series mechanical lock

- Panic hardware (prep provided for the push side):

- Von Duprin 33/35A Series Narrow Stile Rim Exit Device

- Von Duprin 98/99 Series Rim Exit Device

- DORMA 9700 Series Narrow Stile Rim Exit Device

For Primary Swing Panels (no acoustical performance value)

- Deadbolt lock(s) and push/pull handles and key/key European profile cylinder on both sides. Only recommended for end swing panel with door closer by others. Instead of a profile cylinder, an adapter casing is available for use with an SFIC core.

- Latch and deadbolt single motion operated by GU Rondo lever handles and with European profile cylinder. Instead of a profile cylinder, an adapter casing is available for use with an SFIC core.

For Primary Swing Panels Prepped for Supply by Others (no acoustical performance value)

- Latch and deadbolt single motion locking operated by lever handles with locking with a US mortise cylinder that can accommodate standard 5 - 7 pin, SFIC, FSIC, or LFIC cores that currently includes Yale 8808-2 series and Schlage L/LV9000 series only.

- Single latch Schlage ND Series mechanical lock

- Panic hardware (prep provided for the push side):

- Von Duprin 33/35A Series Narrow Stile Rim Exit Device

- Von Duprin 98/99 Series Rim Exit Device

- DORMA 9700 Series Narrow Stile Rim Exit Device

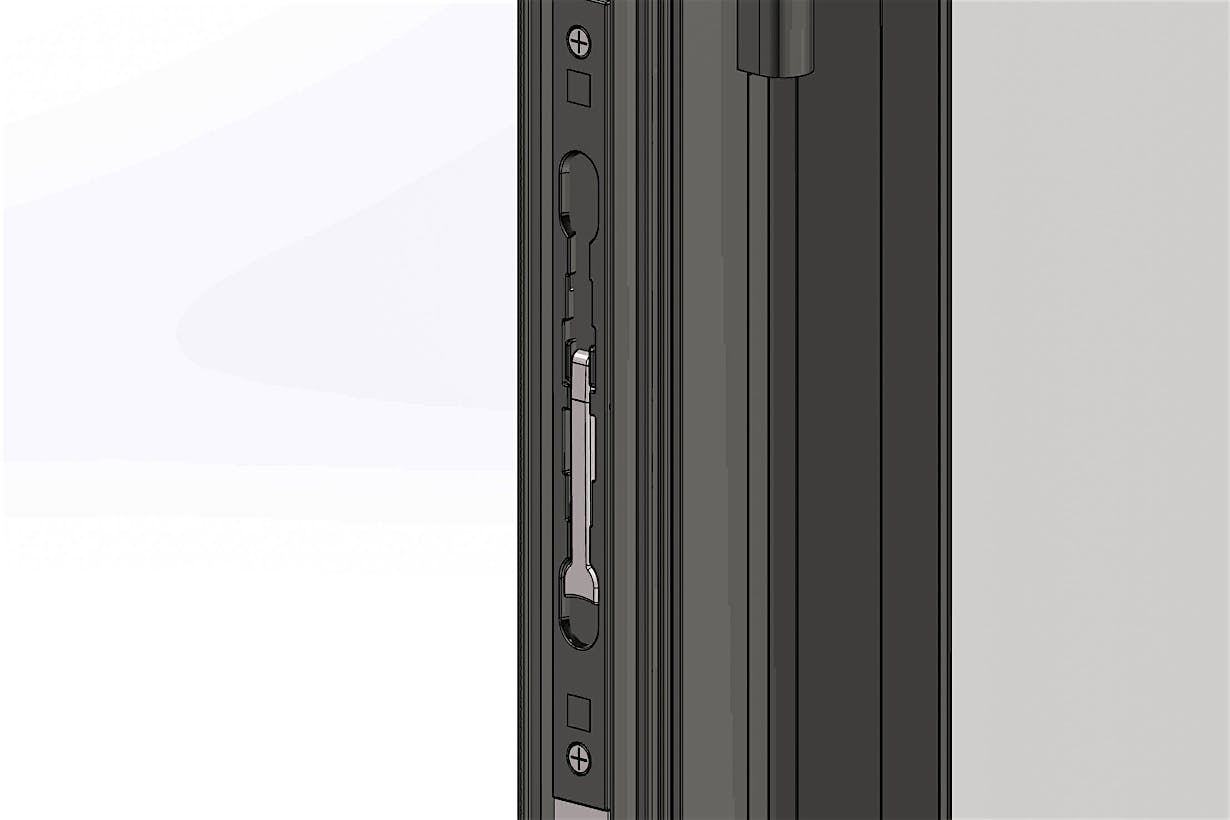

Edge Lock

Standard and Tested Locking for Secondary Swing Panels

Concealed edge lock with top and bottom locking bolts have approximately a 1″ (24 mm) throw for maximum security engagement into the head and floor track. Locking is independently tested for acoustical performance and forced entry.

*For more hardware options, contact NanaWall.

Standard and Tested Locking for Secondary Swing Panels

Concealed edge lock with top and bottom locking bolts have approximately a 1″ (24 mm) throw for maximum security engagement into the head and floor track. Locking is independently tested for acoustical performance and forced entry.

*For more hardware options, contact NanaWall.

Our design team is here to help bring your project to life from sketch to finish. From answering your questions to planning, ordering and optimizing your options, we provide assistance to help you accomplish your goals.

Frequently Asked Questions

There are a number of factors that help us determine the best system for your application including:

- Is this a residential or commercial project?

- Is it an interior or exterior application?

- What city and state is your project located in?

- How big is the opening?

- Is it a ground floor application or a high-rise?

Each system has its own features and benefits engineered to solve specific design requirements. NanaWall provides only the appropriate system for a specific application need. We have four distinct product families: Folding, Sliding, Stacking, and Frameless.

NanaWall is a custom product tailored specifically for your project needs. Numerous features and options make up the price: type of system (we offer 20+), custom opening and panel size, glass type, door hardware, finish choice...to name a few. The best way to determine price is to consult with NanaWall and get a quote, directly from NanaWall, for the exact system that best meets your project requirements and budget. For more information, visit Pricing and Budget Guidelines

We manufacture in Richmond, California, and with our strategic German partner, Solarlux. Operating ISO9000-certified factories in both the US and Germany helps shorten lead times. When discussing your project with your local NanaWall representative, let them know you are interested in having your order expedited.

The lead times vary depending on system selection and design choices. To see our current delivery estimates, click here. To check the status of any order, call 1-(888) 411-NANA and dial extension 255 for Order & Delivery Status.

Watch the Delivery Process video

NanaWall deliver throughout North and Central America. Your local NanaWall representative will best be able to explain the process for obtaining and installing a NanaWall System in your area.