General Maintenance Considerations

Recommended Maintenance of NanaWall Products

1. It is important that the product is installed correctly. A poorly installed unit will not function properly. This will cause more abnormal force or stress on the components and will lead to premature failure. When operating the unit, the panels should generally be able to be moved easily by one person (except when there are very large panels or when there are more than 6 panels folding to one side). All locking points should engage smoothly. There should be no rubbing on the floor and no binding. When the unit is closed, the reveal between panels and head jamb and between panels and sill should be consistent. There should be no daylight seen from the inside. Please have all problems corrected as soon as possible by a qualified technician or an independent NanaWall Certified Installer.

2. From time to time, due to building movement or settlement, a unit may need to be adjusted by a qualified technician or an independent NanaWall Certified Installer to compensate for any building change.

3. It is important that a unit is operated properly. Locking points should be gently opened and closed and not forced. Panels should be opened and closed in the proper manner and sequence. See the Operation section for proper operation.

4. Periodically check for worn or damaged components and replace as soon as possible. A unit with non-working components will subject the other components to increased stress and lead to premature failure. A unit with worn or damaged components will compromise the performance level expected for air and water infiltration, structural loading, and forced entry.

5. Periodically, inspect the sealant/caulking on the exterior perimeter of the unit. It is extremely important that the sealant/caulking remains intact and in good condition. Trim off any old, loose caulking, and seal any gaps with a good quality caulk.

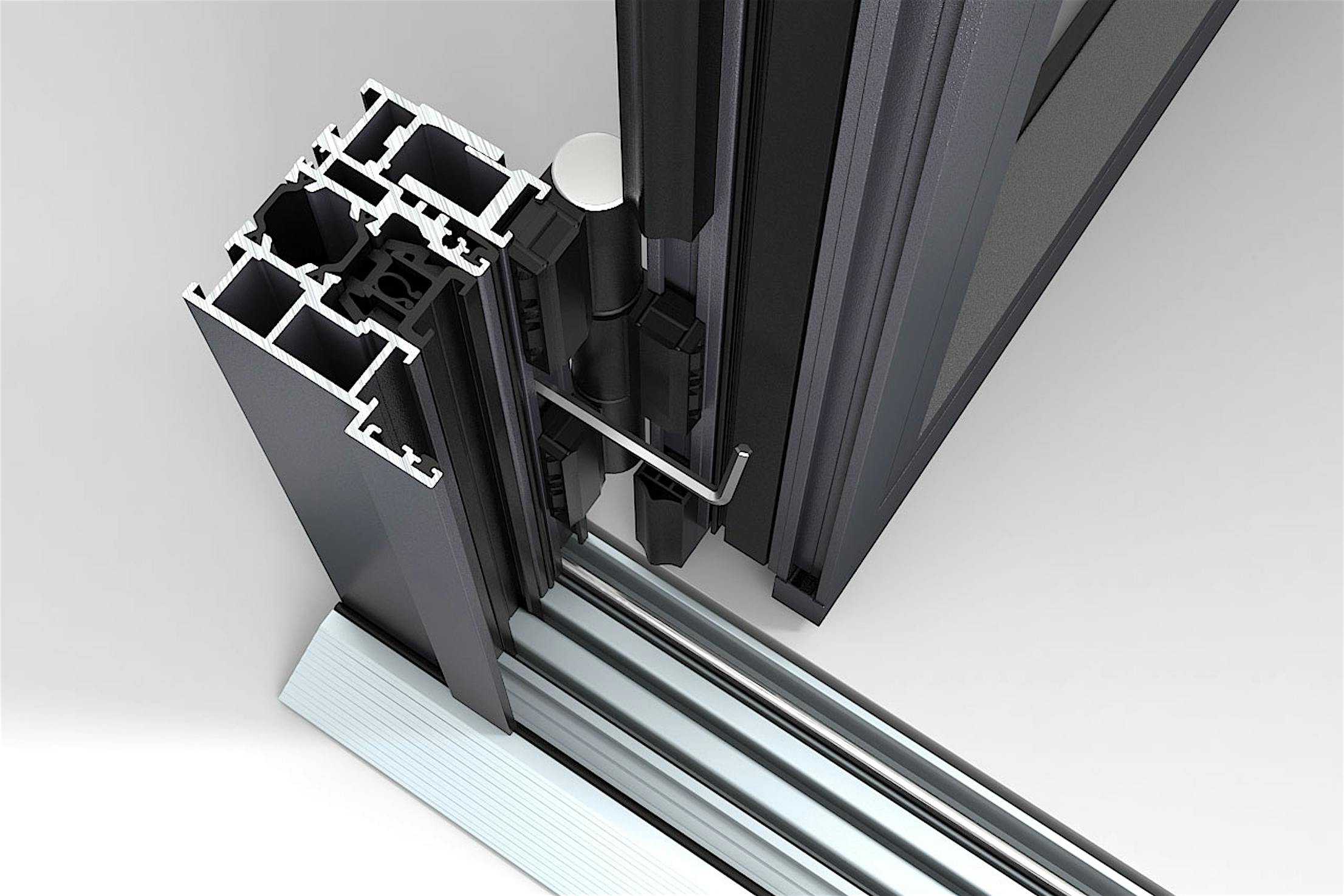

6. Check that all weep holes are clean and clear of any obstructions. Remove debris and other foreign bodies which have dropped into the sill and other parts of the frame immediately to prevent damaging the top guides and bottom rollers. Clean all components as needed. Rinse the bottom track and check if water is exiting the system. Check gaskets for proper seating and condition. Remove dust and any deposits from these gaskets.

A unit with non-working components will subject the other components to increased stress and lead to premature failure.

7. The finished aluminum or wood surface needs periodic cleaning and maintenance. Its appearance may be marred by harsh chemicals, abuse, or neglect. Frequency of cleaning depends on exposure and needs. For aluminum surfaces, generally warm soapy water should be sufficient. Stubborn stains and deposits may be removed with mineral spirits. For wood surfaces, superficial surface dirt can be removed by washing with water and a soft-bristled, long-handled brush. Heavier accumulations can be removed with a mild solution of household detergent. For all surfaces, aggressive alkaline or acid cleaners should not be used. Excessive abrasive rubbing should be avoided. Sealants and weather stripping may be affected by strong organic solvents. Superficial damage to the aluminum surface must be touched up immediately with proper touch up paint.

8. If it is a wood product, the surface should be visually inspected every six months or earlier, depending on the exposure of the NanaWall unit. Periodically repaint or restain the wood as needed. Exposure to the environment will break down the finish and compromise its protective features if not refinished.

9. All hardware, hinges, and handles should be periodically cleaned with a soft cloth and mild cleanser. Excessive abrasive rubbing should be avoided. Please note that oil rubbed brass is a finish that will develop its own unique patina over time.

10. About every three to six months, apply a Teflon based lubricant to all the hinges. If operation of panels gets difficult, or at least every 12 months, clean the stainless steel surface of the track insert and the rollers and apply a Teflon based lubricant to the surface only and wipe off additional residues. The ball bearings of the rollers are encapsulated and maintenance free. Any silicone, other oils, and “dry lube” sprays should not be used.

Connect with a NanaWall expert to answer your questions and explore how we can support your project.

Monday - Friday: 7 AM - 5 PM PST