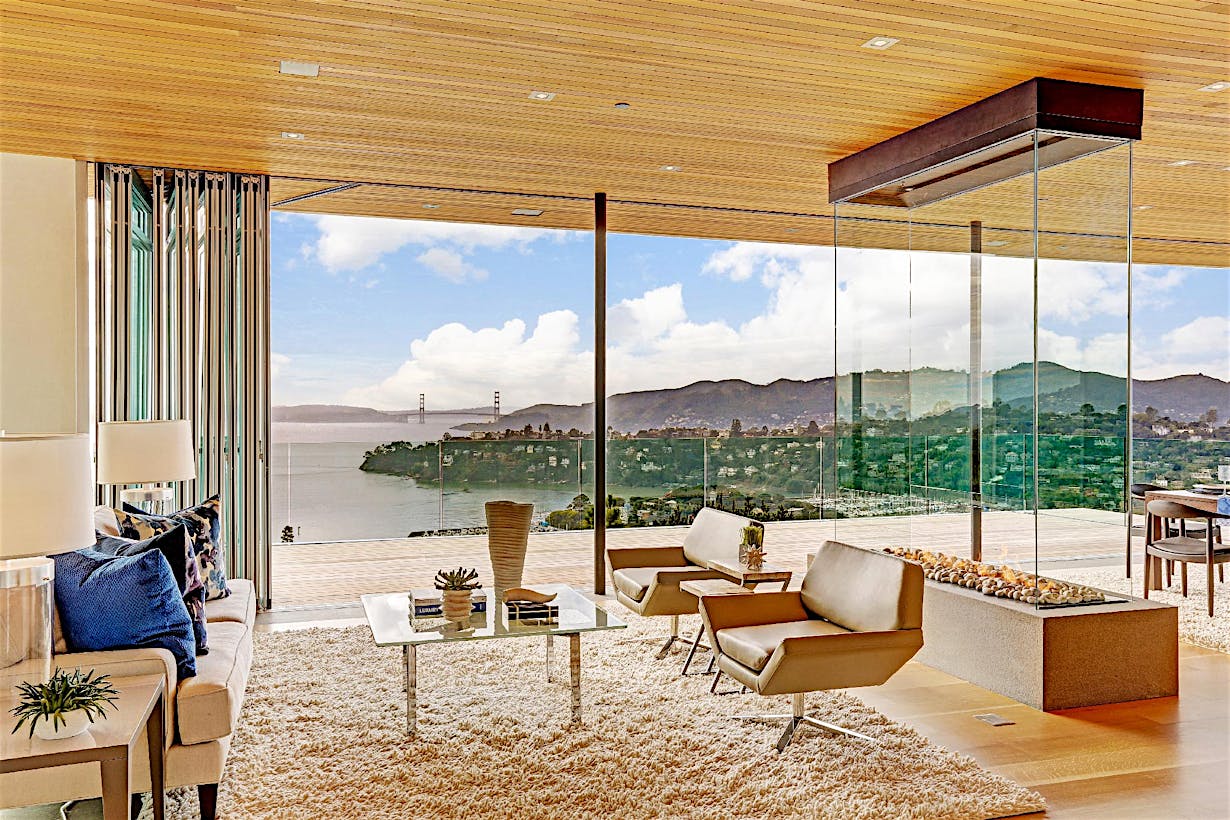

Explore some examples of customized solutions to visualize the versatility of our products. Let us know how we can help bring your design to life.

For over 30 years, we’ve been leading the industry in developing and refining our glass wall systems to create solutions across every application.

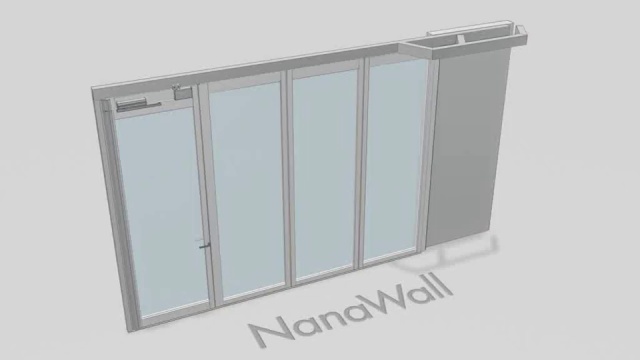

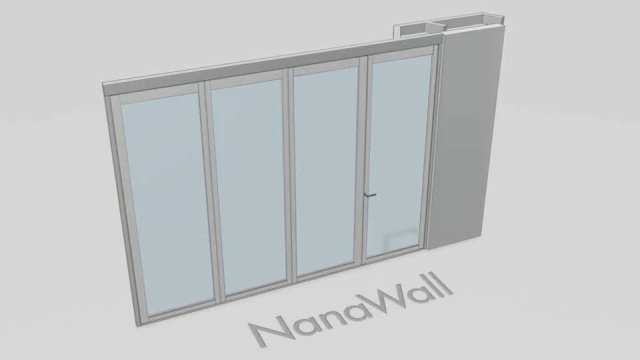

Meat on Ocean

Santa Monica, CA

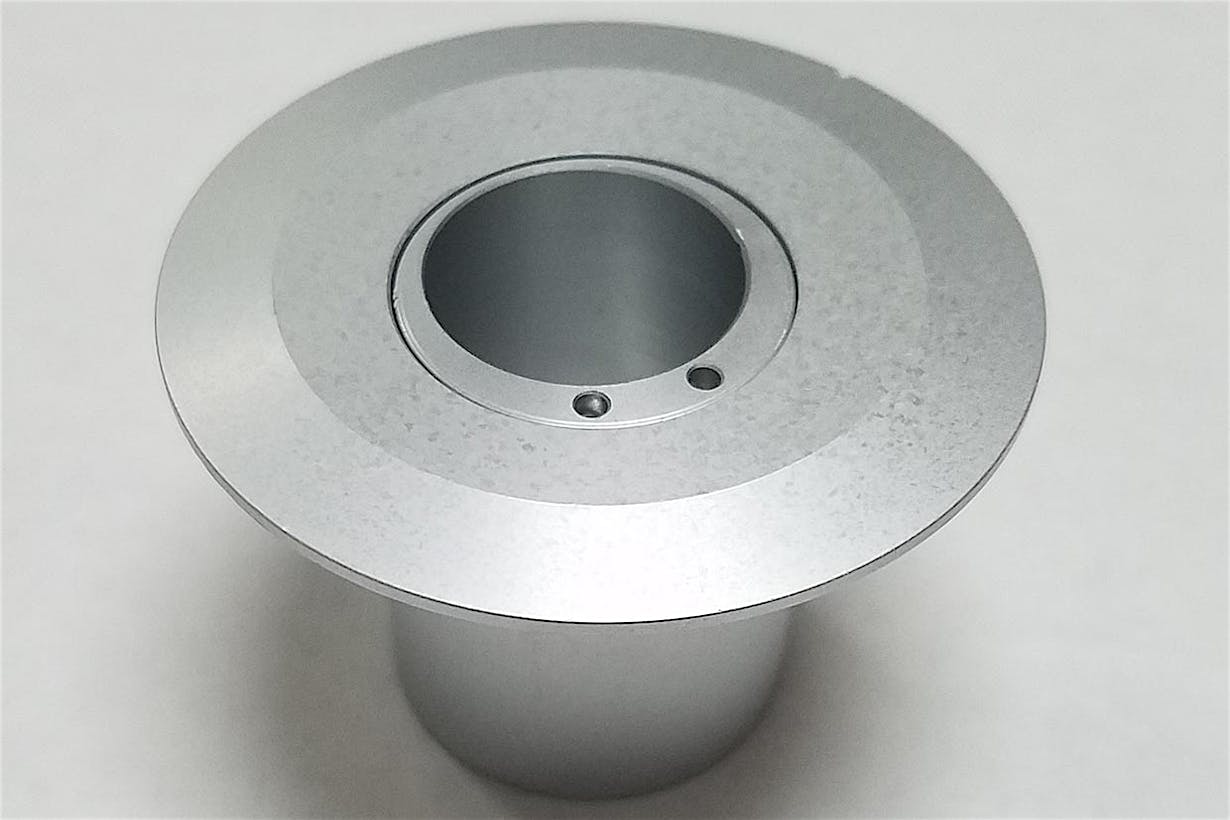

Eccentric Floor Socket

- For certain applications, sills can be eliminated completely

- Provides seamless transition between two spaces

- Locking rods in panels engage in adjustable floor sockets

- For certain applications, sills can be eliminated completely

- Provides seamless transition between two spaces

- Locking rods in panels engage in adjustable floor sockets

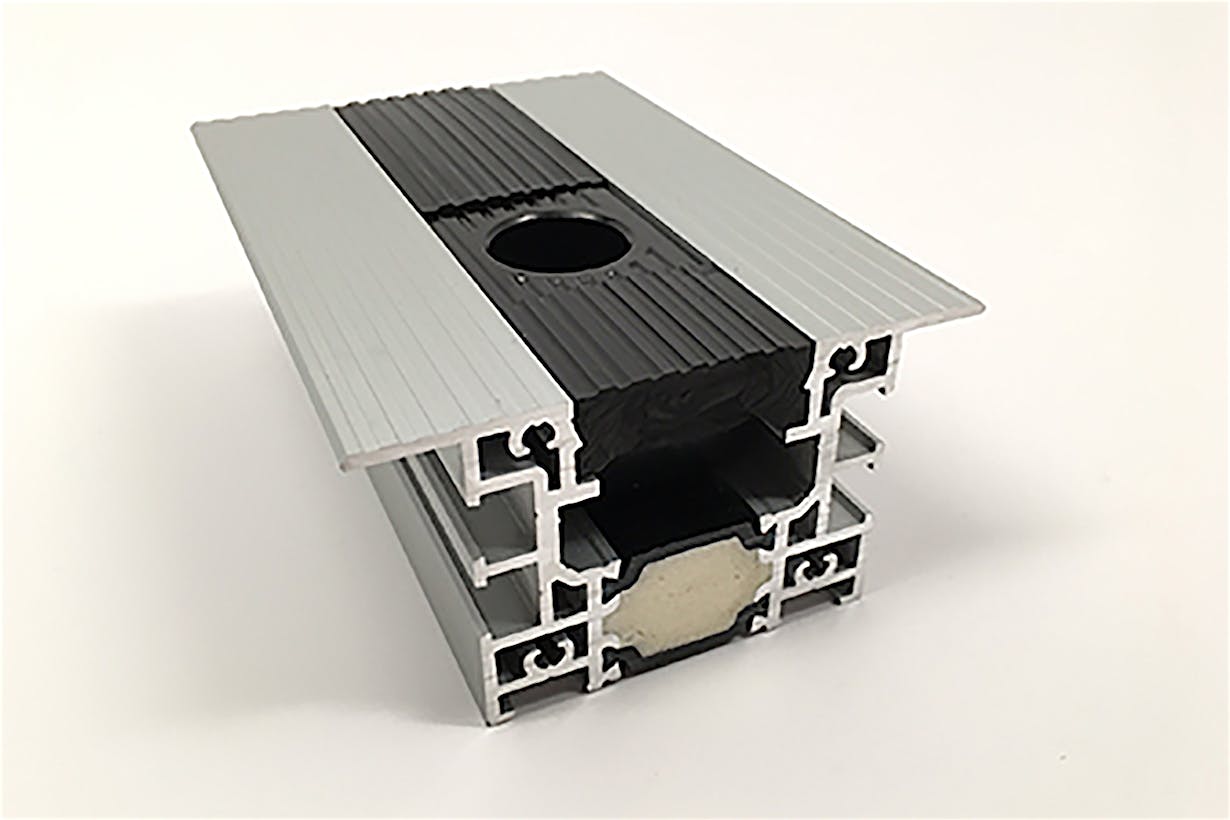

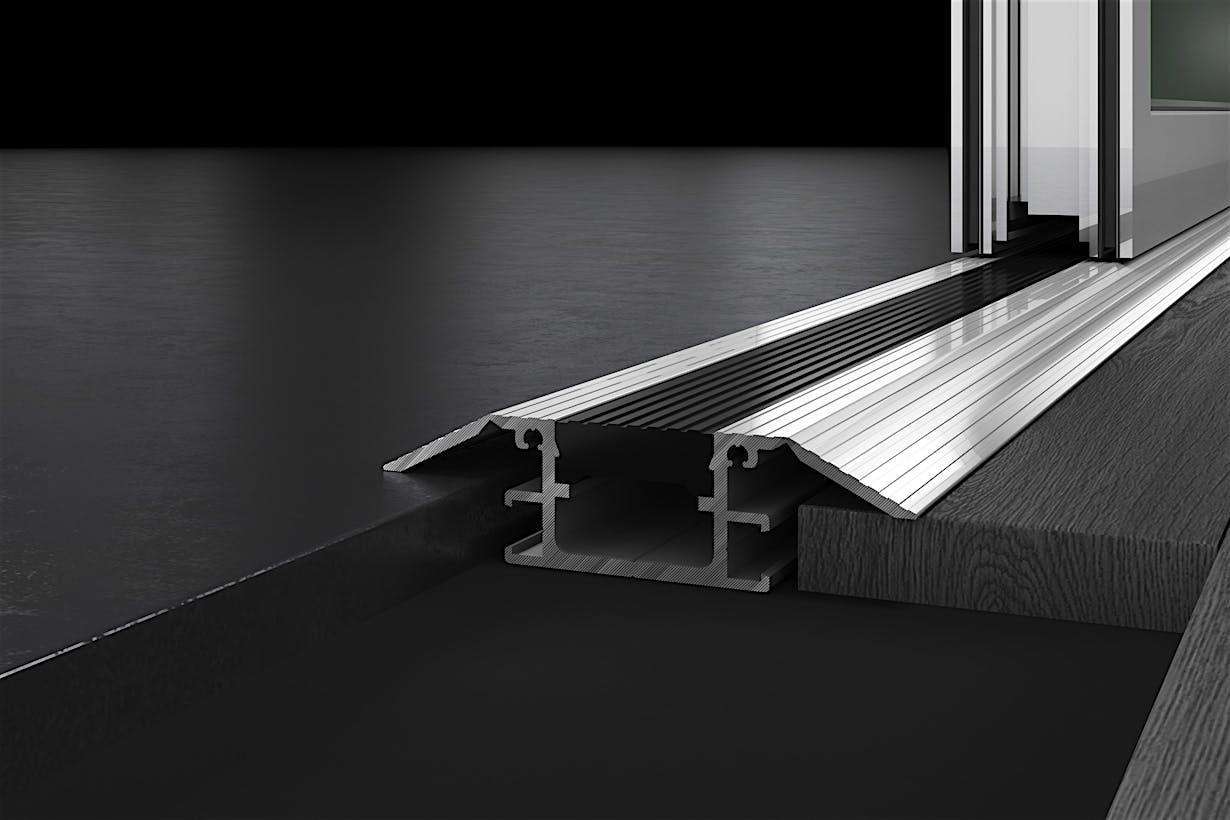

Flush Sill

- ADA Compliant with insert

- For interiors or protected exteriors

- Where water performance is not needed

- Thermally broken for better insulation and energy efficiency

- Available in Clear or Bronze Anodized finishes

- ADA Compliant with insert

- For interiors or protected exteriors

- Where water performance is not needed

- Thermally broken for better insulation and energy efficiency

- Available in Clear or Bronze Anodized finishes

Surface Mounted Interior Sill

- For interiors only

- Sill rests above the subfloor for easier installation

- Adjustable flanges and available insert for ADA compliance

- Available in Clear or Bronze Anodized finishes

- For interiors only

- Sill rests above the subfloor for easier installation

- Adjustable flanges and available insert for ADA compliance

- Available in Clear or Bronze Anodized finishes

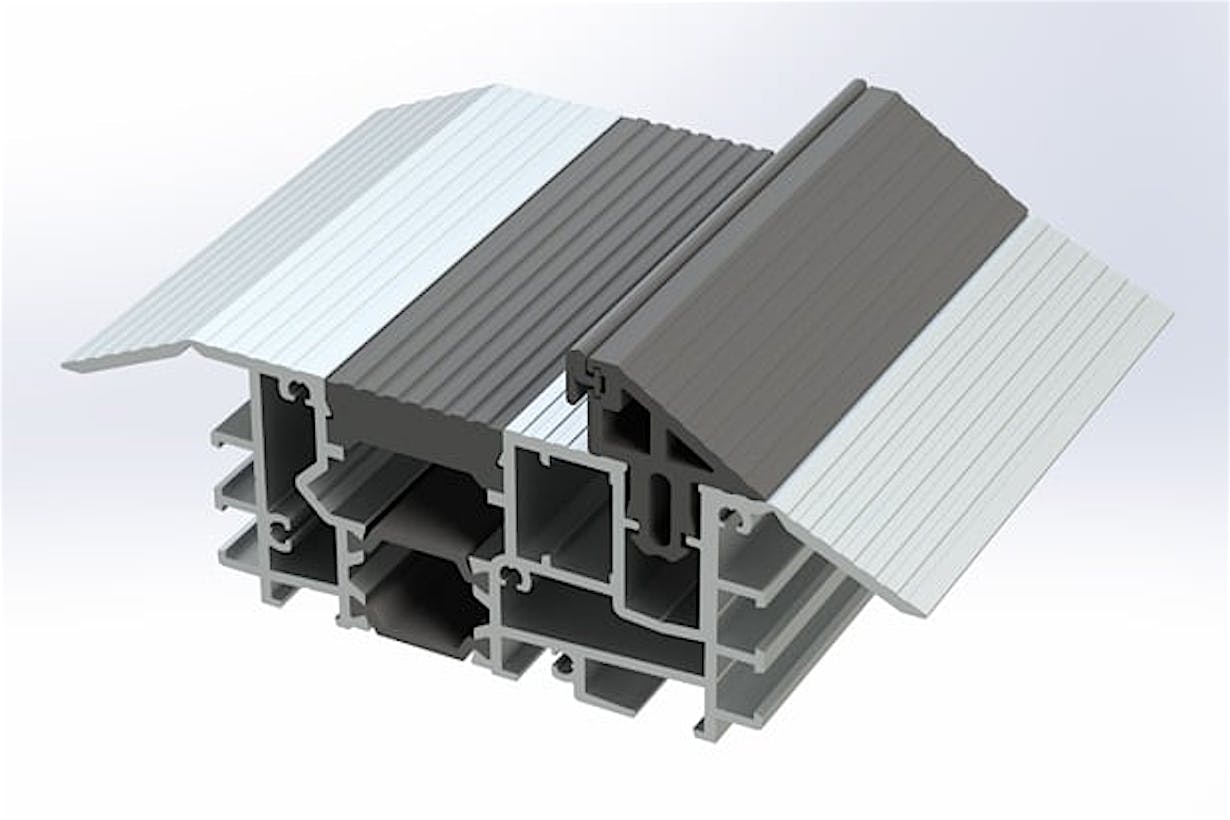

Low Profile Saddle Sill

- Our most popular sill

- Thermally broken for better insulation and energy efficiency

- Partial or full insert available for ADA compliance

- Available in Clear or Bronze Anodized finishes

See Generic Installation Details and Weephole Pattern (Low Profile Saddle Sill)

- Our most popular sill

- Thermally broken for better insulation and energy efficiency

- Partial or full insert available for ADA compliance

- Available in Clear or Bronze Anodized finishes

See Generic Installation Details and Weephole Pattern (Low Profile Saddle Sill)

Low Profile Saddle Sill with UniverSILL®

- When the wall system is closed and higher wind and water performance is desired, the patented, hard rubber UniverSILL adapter can be inserted into the Low Profile Saddle Sill. Compression gasketing on all four sides can be achieved to further reduce air and water infiltration. When the wall system is opened and ADA requirements need to be met, the UniverSILL adapter can be easily removed.

- When the wall system is closed and higher wind and water performance is desired, the patented, hard rubber UniverSILL adapter can be inserted into the Low Profile Saddle Sill. Compression gasketing on all four sides can be achieved to further reduce air and water infiltration. When the wall system is opened and ADA requirements need to be met, the UniverSILL adapter can be easily removed.

Stainless Steel Lever Handles

Stainless steel lever handles and escutcheon plates are available either in a brushed satin, black titanium finish.

Stainless steel lever handles and escutcheon plates are available either in a brushed satin, black titanium finish.

Contemporary Stainless Steel Handle

Stainless steel flat handles are available either in a brushed satin, black titanium finish.

Stainless steel flat handles are available either in a brushed satin, black titanium finish.

Stainless Steel Lever with Return

Solid Brass Lever Handles

Solid brass lever handles and escutcheon plates are available either in an Oil Rubbed Brass, Satin Nickel or a White finish.

Solid brass lever handles and escutcheon plates are available either in an Oil Rubbed Brass, Satin Nickel or a White finish.

Other Flat Handle Options

Flat handles are available in Dark Brown, White Aluminum, White or matching powder coat finish.

Flat handles are available in Dark Brown, White Aluminum, White or matching powder coat finish.

Push Pull Handle

Multipoint Locking with Latch, Deadbolt and Top/Bottom Locking Rods

This option is possible only on primary swing door.

Includes top and bottom Polyamide capped locking rods, deadbolt, a compatible lock set with lockable latch and lever handles on the inside and outside. Depression of handles withdraws latch. Lifting of handles engages rods and turn of key or thumb turn engages deadbolt and operates lock.

Operable from inside and outside.

This option is possible only on primary swing door.

Includes top and bottom Polyamide capped locking rods, deadbolt, a compatible lock set with lockable latch and lever handles on the inside and outside. Depression of handles withdraws latch. Lifting of handles engages rods and turn of key or thumb turn engages deadbolt and operates lock.

Operable from inside and outside.

Two Point Locking

Standard between each pair of bi-fold panels and an option for swing panels. 180-degree turn of handle moves locking rods up or down. Uses 7 mm spindle.

Operable from inside only.

Standard between each pair of bi-fold panels and an option for swing panels. 180-degree turn of handle moves locking rods up or down. Uses 7 mm spindle.

Operable from inside only.

Deadbolt Lock

Possible only on primary or secondary swing panel.

Push Pull handles on both sides with deadbolt(s) operated by a lockset. Lockset option of having key operations on both sides. With a profile cylinder, panel is lockable with a thumbturn from the inside and a key from the outside. To keep the panel from being blown open, this option should be used with a door closer, but note that a door closer is not possible on a swing panel in a folding system that is not attached to a side jamb

Possible only on primary or secondary swing panel.

Push Pull handles on both sides with deadbolt(s) operated by a lockset. Lockset option of having key operations on both sides. With a profile cylinder, panel is lockable with a thumbturn from the inside and a key from the outside. To keep the panel from being blown open, this option should be used with a door closer, but note that a door closer is not possible on a swing panel in a folding system that is not attached to a side jamb

Single-point Single Motion Locking

GU Rhondo lever handles on the inside and outside with single-point single motion locking, emergency egress, interconnected lock for interior application.

GU Rhondo lever handles on the inside and outside with single-point single motion locking, emergency egress, interconnected lock for interior application.

Optional Commercial Locking on Primary Swing Panels

- For interior application, single-point single motion locking operated by GU Rhondo lever handles with European profile cylinder or an adapter to accommodate a 5-7 pin SFIC core (SFIC core supplied by others).

- Push/pull handles on both sides with deadbolt and lockset with key operation. Secured with a European profile cylinder or an adapter to accommodate a 5-7 pin SFIC core (SFIC core supplied by others).

- Single-point single motion locking operated by Adams Rite Steel Hawk 4300 with electrified dead latch.

- Panic hardware (Prepped on interior side only and supplied by others):

- Von Duprin 33/35A Series Narrow Stile Rim Exit Device (with electric latch retraction).

- For interior application, single-point single motion locking operated by GU Rhondo lever handles with European profile cylinder or an adapter to accommodate a 5-7 pin SFIC core (SFIC core supplied by others).

- Push/pull handles on both sides with deadbolt and lockset with key operation. Secured with a European profile cylinder or an adapter to accommodate a 5-7 pin SFIC core (SFIC core supplied by others).

- Single-point single motion locking operated by Adams Rite Steel Hawk 4300 with electrified dead latch.

- Panic hardware (Prepped on interior side only and supplied by others):

- Von Duprin 33/35A Series Narrow Stile Rim Exit Device (with electric latch retraction).

Our design team is here to help bring your project to life from sketch to finish. From answering your questions to planning, ordering and optimizing your options, we provide assistance to help you accomplish your goals.

Frequently Asked Questions

There are a number of factors that help us determine the best system for your application including:

- Is this a residential or commercial project?

- Is it an interior or exterior application?

- What city and state is your project located in?

- How big is the opening?

- Is it a ground floor application or a high-rise?

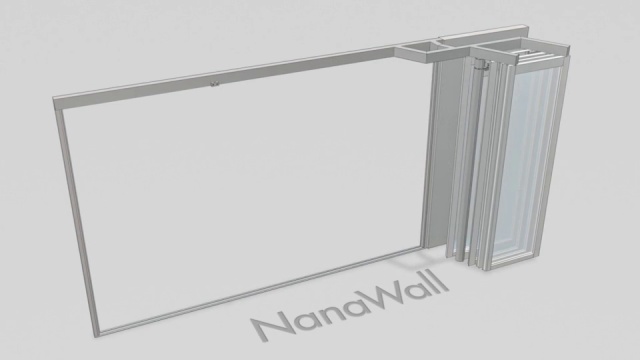

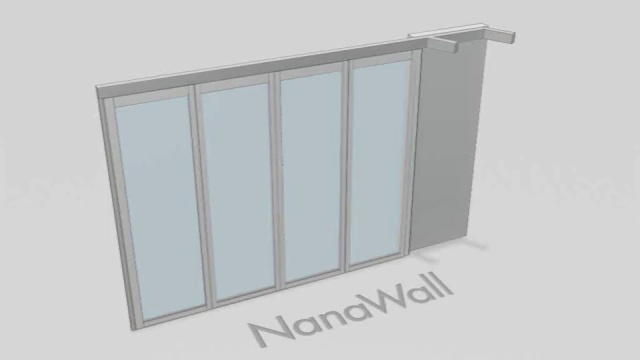

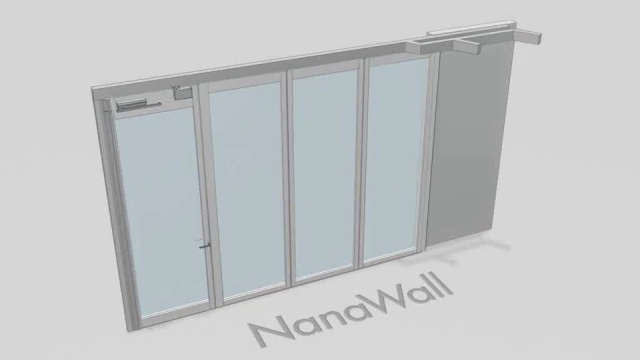

Each system has its own features and benefits engineered to solve specific design requirements. NanaWall provides only the appropriate system for a specific application need. We have four distinct product families: Folding, Sliding, Stacking, and Frameless.

NanaWall is a custom product tailored specifically for your project needs. Numerous features and options make up the price: type of system (we offer 20+), custom opening and panel size, glass type, door hardware, finish choice...to name a few. The best way to determine price is to consult with NanaWall and get a quote, directly from NanaWall, for the exact system that best meets your project requirements and budget. For more information, visit Pricing and Budget Guidelines

We manufacture in Richmond, California, and with our strategic German partner, Solarlux. Operating ISO9000-certified factories in both the US and Germany helps shorten lead times. When discussing your project with your local NanaWall representative, let them know you are interested in having your order expedited.

The lead times vary depending on system selection and design choices. To see our current delivery estimates, click here. To check the status of any order, call 1-(888) 411-NANA and dial extension 255 for Order & Delivery Status.

Watch the Delivery Process video

NanaWall deliver throughout North and Central America. Your local NanaWall representative will best be able to explain the process for obtaining and installing a NanaWall System in your area.